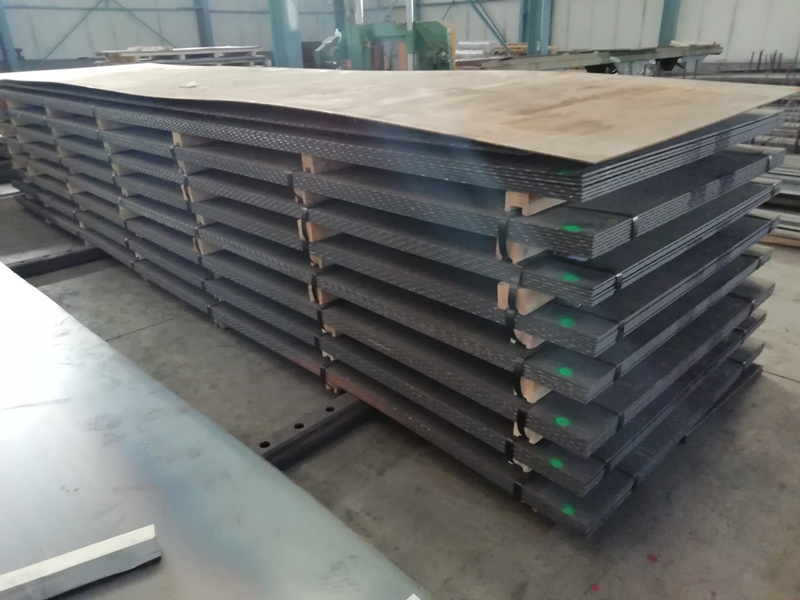

Hot rolled steel sheet

USES OF HOT ROLLED SHEET:

- railway accessories;

- storage compartments - vehicle parts;

- various structural applications;

- shipping industry;

- construction of boilers and other recipients under pressure;

- manufacture of machinery and heavy equipment;

- container production.

When choosing materials for a particular application, it is important to know the difference between the various types of steel available, the type of lamination and the advantages of their inclusion in your industrial or construction project.

The hot rolled sheet is made of steel heated above recrystallization temperature. The procedure continues by successive rolling and pressing by rollers until the desired thickness is obtained. This leads to a flexible material, which is not brittle.

This type of sheet is ideal for applications where thickness, strength and training capacity are important.

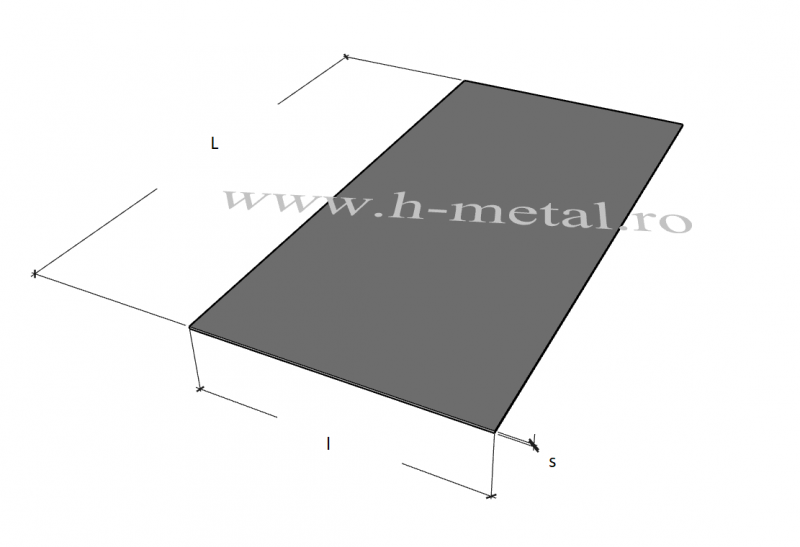

Technical data:

Production standard for hot rolled sheets - medium thickness: according EN 10051

Production standard for heavy plates: according EN 10029 / DIN 1543

Surface conditions and dimensions tolerances: according EN 10029 si EN 10051

Steel grades: according EN 10025 and EN 10028 - S235JR, S235JRG1, S235JRG2, S275JR, S355JO

Quality certificate: type 2.2 or 3.1B, according to EN 10204