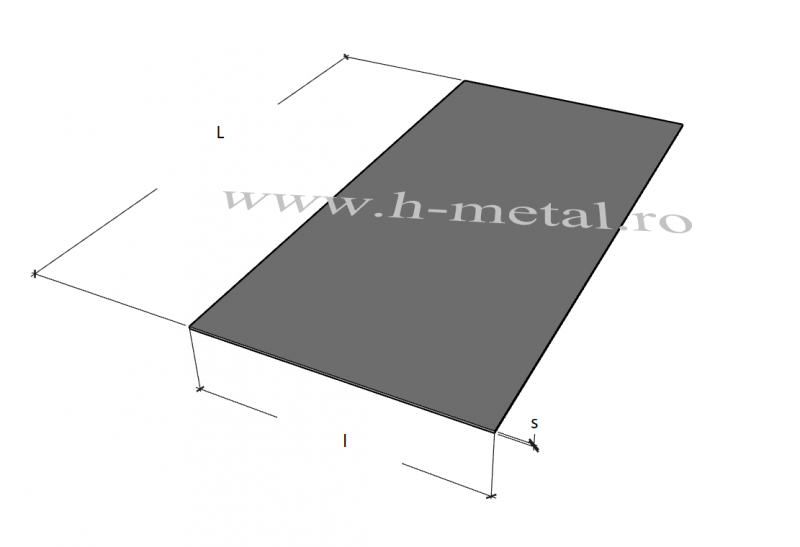

Cold rolled steel sheet

USE OF THE COLD ROLLED SHEET:

Pickled sheet obtained by cold drawing. The steel is rolled and pressed successively by rollers for thinning, at a temperature below the recrystallization temperature, till the desired thickness is obtained. Cold drawing reduces the thickness of the processed material and one achieves stricter thickness tolerances than by hot-rolling.

Cold-drawn sheet has excellent electromagnetic, formability and weldability properties. It is suitable for the manufacture of various products by bending and pressing. It is available in a variety of sizes, with useful features in a wide range of applications.

To prevent rusting, the cold-drawn sheet can have an oily film, which is easily removed.

The cold-drawn sheet can be painted or zinc-coated. Before undergoing this process, the sheet must be carefully cleaned by means of a solvent or an alkaline solution.

Applications:

- vehicles;

- home appliances;

- furniture;

- storage racks;

- highway parapet walls;

- various metal constructions;

- agricultural machinery;

- manufacturing of shingle-like sheet;

- household items;

- advertising industry;

- piping;

- panels.

Technical data for cold rolled sheets, pickled plate:

Production standard for cold rolled sheets: according EN 10131 / DIN 1541

Steel grades according to EN 10130 / DIN 1623: DC01, DC02, DC03, DC04

Surface and dimensions tolerances: according to EN 10131 / DIN 1541

Quality certificate: type 2.2 or 3.1B, according to EN 10204