What are the differences between laminated corner – embossed corner

It is very important to know what the differences are between a laminated corner and an embossed corner, before carrying out a project.

These two angles are metallurgical products made of steel, only they are manufactured by two totally different methods.

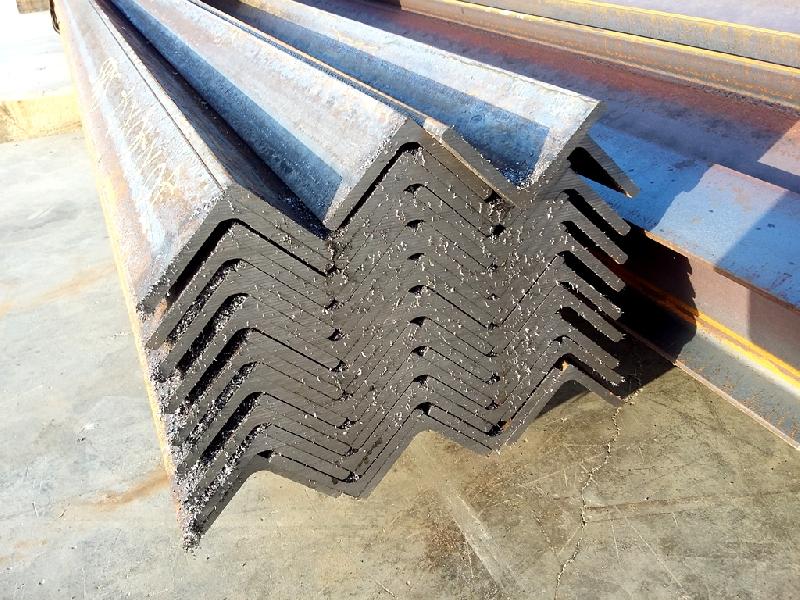

A laminated cornice is made by the hot or cold lamination process. It has a transverse section, made of carbon steel, in the form of a right angle with equal or unequal sides.

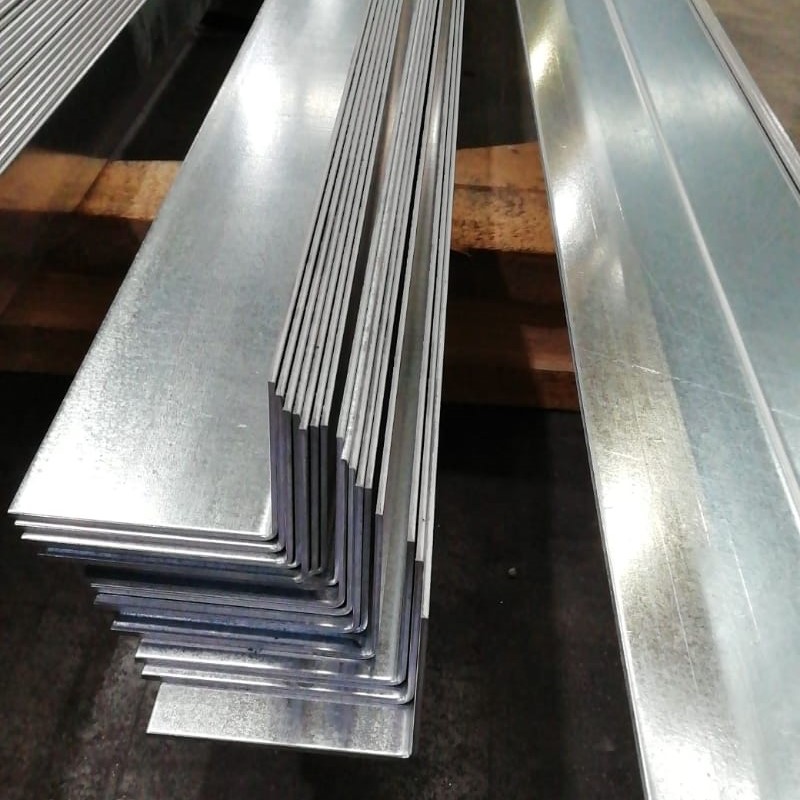

On the other hand, an embossed corner is obtained from sheet metal picked up by the cold bending technique on the abkant.

Compared to a hot-rolled corner, the one obtained by embossing has the disadvantage that the radius of the corner is much larger. Thus, the thicker the board from which the corner is made, the larger the radius of the corner, the useful part of the side remaining smaller.

In most cases, the angle obtained by lamination is used, but there are also applications where it is necessary to use the cold-bent angle with a round corner. It depends on the specifics of the project that needs to be done and both angles can be used.

Laminated corner and embossed corner – advantages and uses

The major difference between these two corners is that they were manufactured by two different methods.

Advantages of embossed cornice:

- shortens labor times;

- has low costs;

- a wide range of wing thicknesses and sizes can be obtained;

- ensures a higher strength-to-weight ratio compared to a laminated angle;

- versatile and adaptable.

Embossed cornice uses:

- metal constructions;

- industrial subassemblies;

- elements for constructions;

- components from the furniture industry, etc.

In general, an embossed angle is used when its sides must be drilled, this operation being performed before embossing, when the sheet is flat.

Advantages of laminated cornice:

- mechanical resistance;

- can be riveted or welded;

- can be made with large thicknesses 3-24 mm;

- has a perfect right angle, etc.

Uses of laminated cornice:

- various metal parts;

- metal frames;

- metal supports, frames and chassis;

- parts and parts for machines;

- gates, fences, transmission towers;

- shelves and storage containers;

- power line poles, etc.

In the figure below you can see the main manufacturing differences between hot rolled corner and cold pressed corner:

H Metal quickly distributes, throughout the country, both rolled and pressed products.

We are waiting for your requests at office@h-metal.ro

<< Inapoi