Categories of corrugated sheet and the differences between them

H Metal supplies different categories of corrugated board – steel – galvanized – stainless steel – aluminum.

MECHANICAL RESISTANCE

In terms of resistance to mechanical stress, stainless steel sheet behaves best. The next plate with good mechanical resistance is corrugated steel sheet or galvanized corrugated sheet, both of which are based on simple or hot-dip galvanized steel.

When we compare the same sheet thickness, the least resistant to mechanical stress is aluminum sheet

MALEABILITY

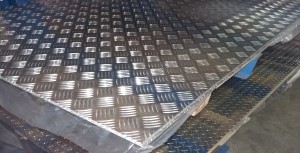

Aluminum sheet can be processed the easiest. The most complicated pieces and shapes can be made from aluminum corrugated sheet. The ones that are not so permissive in processing are stainless steel sheet and steel sheet.

In some situations when the thickness is too high and the embossing is deep, there is a possibility that the stainless steel sheet will crack.

Steel corrugated sheet, galvanized corrugated sheet as well as stainless steel corrugated sheet are sheets that are difficult to process through embossing/bending operations, both due to the composition of the material and the existing striations on the surface of the sheet.

Categories of corrugated board – resistance to corrosion

The most resistant to corrosive agents is stainless steel.

Thus, stainless steel corrugated sheet is used in projects with a high budget and a very long life cycle. This is used in the construction of tall buildings, such as skyscrapers, bridges, the automotive industry, the aviation industry, etc.

Also, stainless steel sheet is used due to its resistance to corrosion and its antiseptic properties. Being used in the food and pharmaceutical industry.

Close to corrosion resistance is aluminum sheet, having a life cycle as close as possible to that of stainless steel sheet.

Galvanized sheet is a sheet that is used for low-budget projects, such as: fencing systems, ramp cladding, car floor cladding, etc. And the smooth galvanized sheet is used to make piping for air circulation.

Less resistant to corrosion is corrugated steel sheet.

PRICE AND DELIVERY

In terms of price, the cheapest corrugated sheet is steel sheet.

This is followed by corrugated galvanized sheet, aluminum sheet and the most expensive being stainless steel corrugated sheet.

The lifetime of a hot-dip galvanized product used in medium corrosion conditions is about 15-20 years. If the hot-dip galvanized products are installed in areas with high salinity or exposed to corrosive agents in a higher than average concentration. Then their life span can be halved.

Thus when making products that are intended to be used for long periods of time. A very good solution is the most expensive, i.e. corrugated stainless steel sheet.

In order to send a concrete offer for the price of corrugated sheet, please send us the following details to the contact email, respectively office@h-metal.ro:

• Thickness of ribbed sheet, without ridges and plus ridges, sheet width, sheet length, number of sheets;

– Material quality, both for aluminum and stainless steel;

• The city of destination, in order to be able to send you a transport cost proposal.

<< Inapoi