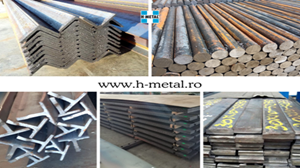

Metal platform structure made of rolled steel products

Metal platform structure, made of laminated steel products, for a modern base for initiation, training and SUP competitions.

The rolling process ensures an even distribution of material, reducing the risk of internal defects.

Hot rolled steel is an essential material used in construction for the construction of support structures due to its excellent mechanical properties and versatility.

It is ideal for applications requiring high load-bearing capacity, such as bridges, large structures and heavy machinery. It is also more wear resistant and can be used in high stress areas.

MATERIALS SUPPLIED BY H METAL FOR METAL PLATFORM STRUCTURE:

– steel angle 120x80x8 mm;

– T steel section 100×11 mm.

What advantages do rolled steel products offer:

Quick assembly – rolled steel components are assembled quickly, which reduces construction time.

Versatility – can be used in various shapes and sizes to suit project requirements.

Sustainability – steel is 100% recyclable, making it an environmentally friendly choice.

Choice of materials

Steel angle is often used to create frames and supports due to their shape which offers good resistance to bending and torsion.

T sections are useful for applications requiring bending resistance in two surfaces and for intermediate supports.

Load analysis

In order to design a metal support structure, static and dynamic loads (dead weight, payload, wind, snow, etc.) must be calculated.

Make sure that the chosen materials can support the calculated loads.

Design and layout of components

Frames and supports

You can use angle brackets to form base frames and supports. Profiles can be arranged in A, H or other suitable configurations.

Beams and transoms

You can use T sections to make beams and transoms. They provide additional support and distribute loads evenly.

H Metal supplies laminated steel products used for various metal structures.

Quotations are made punctually according to size, quality and quantity. Please send us these details to office@h-metal.ro.

<< Inapoi