History of steel

Steel is an alloy of iron and other elements: carbon, manganese, phosphorus, sulfur, silicon, traces of oxygen, nitrogen and aluminum. Carbon and the other alloy elements act as a hardening agent.

Steel has carbon content below 2.11%; iron-carbon alloys containing carbon over 2.11% are called cast iron.

The history of steel begins in ancient times. The oldest steel object is a piece of hardware, excavated in an archaeological site in Anatolia (Kaman-Kalehoyuk) dating back approximately 4000 years.

When the carbon content is over 0.3%, the material becomes hard and brittle if it is sunk in water at a temperature of 850-900 degrees Celsius. Its fragility may be reduced by reheating at 350-500 degrees Celsius, a process called hardening. Judging by the micro-structure of the remaining artifacts, the Egyptians knew about this type of heat treatment around 900 BC. Thus, they made an ideal material for the manufacture of swords and knives. There is also evidence of heat-treated steel during the Han dynasty (206 BC – 25 AD). However, ancient civilizations did not fully master the methods of steel manufacturing, its uses were limited and subject to very long making processes.

The era of the legendary Damascus steel is between 300 BC – 1700 AD. The secrets of making this steel were lost in time, but the artifacts remained. The history of this steel has its beginnings in India, around 300 BC, but it gained recognition during the Crusades of the Middle Ages. Damascus steel could be bent under pressure without breaking. Recent studies suggest that carbon nanotubes were included in its structure, which would explain some of its legendary qualities.

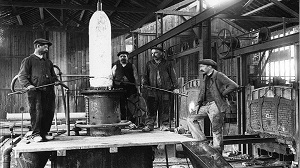

A major breakthrough occurred in 1751, when Benjamin Huntsman established a steel mill in Sheffield, England. Here, the steel was obtained by melting iron ore and cast iron in clay melting pots at a temperature of 1500-1600 degrees Celsius, using charred coal as fuel. Sheffield became the center of melting pot steel production. In 1873, the peak year, production was about 110,000 tons, about half of the world production. The process spread to Sweden and France and then to Germany, where it is associated with Alfred Krupp’s works, in Essen. This process allowed the production of alloy steels for the first time, as the alloying elements could be added to the melted metal in the melting pot.

The process has been in decline since the early 20th century. It is believed that the last melting furnace was operational in Sheffield until 1968.

Before 1860, steel was an expensive product, manufactured in small quantities. The metal structures were made of wrought iron or cast iron.

The modern era of steel manufacturing is linked to the name of the British metallurgist Henry Bessemer. In the Bessemer process, raw cast iron is transformed into steel by blowing air through it, after its removal from the furnace. The process demonstrated by Bessemer in 1856 became successfully operational in 1864. This process is one of the most important production developments of the modern era. A similar process was used in the United States by William Kelly in 1851, patented in 1857.

A difficulty in the Bessemer process was that only low-phosphorus and sulfur-containing cast iron could be transformed.

An alternative process of steel manufacturing was developed in 1860 by William and Friedrich Siemens, in Great Britain, and Pierre and Emile Martin, in France. The open furnace was powered by air and combustible gas, which were preheated by burnt gases to 800 degrees Celsius. A flame temperature of 2000 degrees Celsius was attained, which was enough to melt the charge. Melted cast iron, cold scrap or a combination of the two could be used. By 1950, 90% of steel manufactured in the United Kingdom and the United States was made using an open furnace. But this process was time consuming.

Towards the end of the 19th century, with the development of electricity, it became possible to use electricity as source of energy in steel manufacturing. This is how the electric arc furnace was made.

It is a technology that uses 100% steel scrap, ideal for the manufacturing of low-alloy steel. In 1948, another process was developed by Robert Durrer, known as oxygen-based convector or LD convector (named after the Austrian cities of Linz and Donawitz). It is a refined version of the Bessemer process, the air blowing is replaced by oxygen blowing. Thus, capital costs, melting time and increased productivity decreased. Since 1960, the oxygen-based process has replaced open furnace and Bessemer process on both sides of the Atlantic.

<< Inapoi